As Seen On: news.thomasnet.com February 11, 2020

Reduces Energy Consumption Up To 50%

Toronto, February 10, 2020 – Armstrong Fluid Technology has announced the launch of OPTI-POINT™, a self-learning optimization technology that enables Active Performance Management by creating a digital twin of a mechanical system and learning its operating characteristics in real time.

OPTI-POINT optimizes system efficiency and reduces energy consumption by as much as 50% compared to traditional system designs. It also safeguards system optimization by addressing mechanical drift and performance degradation. Employing predictive diagnostics and condition-based maintenance, OPTI-POINT minimizes plant operating costs.

Read More

Topics:

Design Envelope,

In The Media,

Optimization Service,

OPTI-POINT

As Seen On: empoweringpumps.com February 5, 2020

Armstrong Fluid Technology has announced the launch of Design Envelope EVERCOOL™, a new solution for rapid deployment in mission critical cooling applications.

Design Envelope EVERCOOL is an automation platform for mission critical cooling systems. The EVERCOOL platform offers pre-engineered, feature-rich options that can be configured on-site. The platform meets the stringent requirements of the Uptime Institute for Tier III data centers, while avoiding the traditional requirements of extensive site programming and customization. EVERCOOL reduces site commissioning time by up to 30% and reduces overall energy consumption, coordinating cooling system operation to reduce energy costs by as much as 40%.

Read More

Topics:

Design Envelope,

Plant Automation,

In The Media,

EVERCOOL

As Seen On: ibm.com December 09, 2019

How a Canadian-owned global company is using artificial intelligence technology to make an impact on building management

We aim to elevate the industry to a high plane.” These words were spoken in 1920 by Samuel Armstrong, founder of Armstrong Fluid Technology. Since that time, the company has taken pride in innovative contributions to engineering. They don’t simply create pumps, they develop intelligent, energy-saving systems. These systems are not only saving money for customers, but helping to protect the planet. Addressing the topic of sustainability, Armstrong’s Global Performance Management Services Manager, Tunji Asiwaju states, “Our goal, and the goal of many who rely upon our services, is energy sustainability. We’re using AI and advanced analytics from IBM to help organizations throughout the world to reduce their carbon footprint and achieve their net zero goals.”

Read More

Topics:

Design Envelope,

Sustainability,

In The Media,

Pump Manager,

Net Zero Commitment

As Seen On: empoweringpumps.com November 21, 2019

Armstrong Fluid Technology has introduced the enhanced Design Envelope IPC 9521 Integrated Plant Control System designed to significantly improve the operating efficiencies of plants using either identical or non-identical chillers.

Designed with advanced operating algorithms to reduce energy and water consumption, the TowerMax option is an optimization feature that can help variable speed chiller plants achieve up to 45% energy savings. It compliments both new and existing Building Management Systems (BMS) and works with all brands of chillers and cooling towers to meet the requirements of Green Mark, an industry-leading green building rating system.

Read More

Topics:

Design Envelope,

IPC 9521,

In The Media,

TowerMax,

Integrated Plant Control System

As Seen On: news.thomasnet.com December 03, 2019

Armstrong Fluid Technology has been honored by the Sheet Metal and Air Conditioning Contractors National Association (SMACNA) of Brazil with prestigious industry awards for its key role in two major projects.

SMACNA recognized Armstrong with its New Project of the Year Award for the company’s involvement with the Patteo Shopping Mall in Olinda, Pernambuco, Brazil. The company was also one of the recipients of SMACNA’s Retrofit (Energy Upgrade) Project of the Year Award for its contributions to the Hotel Unique retrofit project in Sao Paulo, Brazil.

Read More

Topics:

Awards,

Design Envelope,

Energy Upgrade,

Retrofit,

In The Media

As Seen On: usgbc.org December 04, 2019

Did you know that it’s possible to save up to 40 cents per square foot, while reducing the timeline to reach your sustainability goals by a third?

There are few building systems that can have such a dramatic impact on tenant productivity, quality of life, operating efficiency and business sustainability as the HVAC system. Performance drift in HVAC systems is a common issue that leads to wasted energy and increase in greenhouse gas (GHG) emissions. According to the International Energy Agency, the construction and operation of buildings is responsible for over 39% of energy-related GHG emissions, a large part of which can be attributed to inefficient HVAC technologies.

Read More

Topics:

Design Envelope,

Energy Saving,

Energy Upgrade,

Sustainability,

In The Media,

Energy Efficiency

As Seen as meuc.co.uk (page no 26): September 2019

Valuable collection

Data collection and communication by individual devices is a powerful weapon in the battle for energy efficiency. Energy Upgrade Leader at Armstrong Fluid Technology, Jason Cox, shows how pumps can lead the charge.

Pump technology can play a significant part in industry’s bid to rein in energy use. Through data analytics and automation, pumps can optimise efficiency by reacting swiftly to changes in demand. A vital design consideration that is key in this role is decentralised data collection – the collection of data from energy-using devices

themselves, rather than simply metering energy usage across a site.

Read More

Topics:

Design Envelope,

Energy Upgrade,

HVAC System,

In The Media,

Energy Efficiency

As Seen on heatinghelp.com - May 29, 2019

Armstrong Fluid Technology’s has announced the availability of an innovative new capability on Pump Manager, an Active Performance Management Service, that can detect and alert building managers about impending pump cavitation.

Effective immediately, Design Envelope pumps will have the capability to detect cavitation and deliver an alert to a previously established contact.

Read More

Topics:

Design Envelope,

In The Media,

Pump Manager,

Active Performance Management,

Cavitation

As Seen on empoweringpumps.com - April 15, 2019

Armstrong Fluid Technology has announced the availability of six new Design Envelope pump models engineered specifically for low-flow, high-head applications.

With the current emphasis on energy and cost savings in buildings of all types, there is a growing requirement for pumps that serve lower flow ranges. To meet this customer demand, Armstrong has added 3 new Design Envelope Tango models

Read More

Topics:

Design Envelope,

HVAC,

In The Media

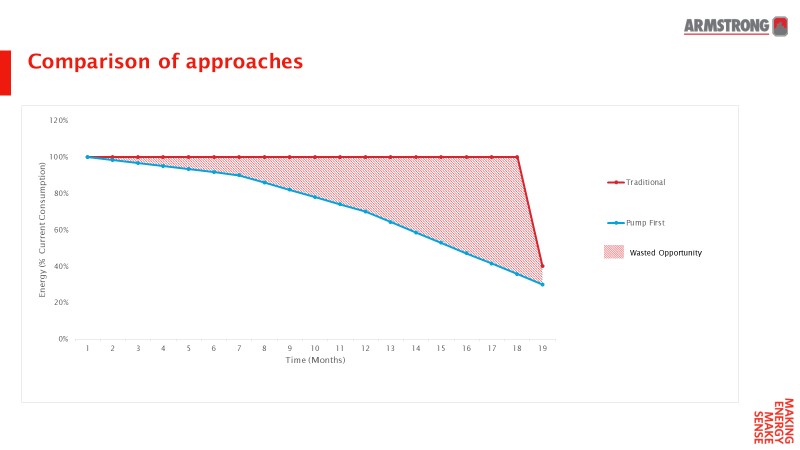

It is time to rethink how energy upgrade projects should be managed. It frequently takes as long as a year and a half to reach the implementation stage of a capital expenditure energy saving project. Typically, the first 6 months are spent collecting data, months 6 to 9 involve a data analysis phase, then technology solutions and a business plan are developed in months 9 to 12. Over the next 6 months stakeholders make their decisions until (18 months after initial discussions) the project is implemented. During that year and a half, not a single kW of energy is saved. With the latest generation of Armstrong Design Envelope (DE) pump technology, however, building owners and occupiers could be saving energy from day 1, month 1 of the initial discussions.

Read More

Topics:

Design Envelope,

Energy Upgrade,

In The Media,

Active Performance Management