As Seen On: empoweringpumps.com March 2, 2021

Blackburn Meadows, Sheffield

An important district heating scheme in Sheffield, which generates heat and energy from waste wood, has come to fruition with the help of an integrated packaged pump solution from Armstrong Fluid Technology.

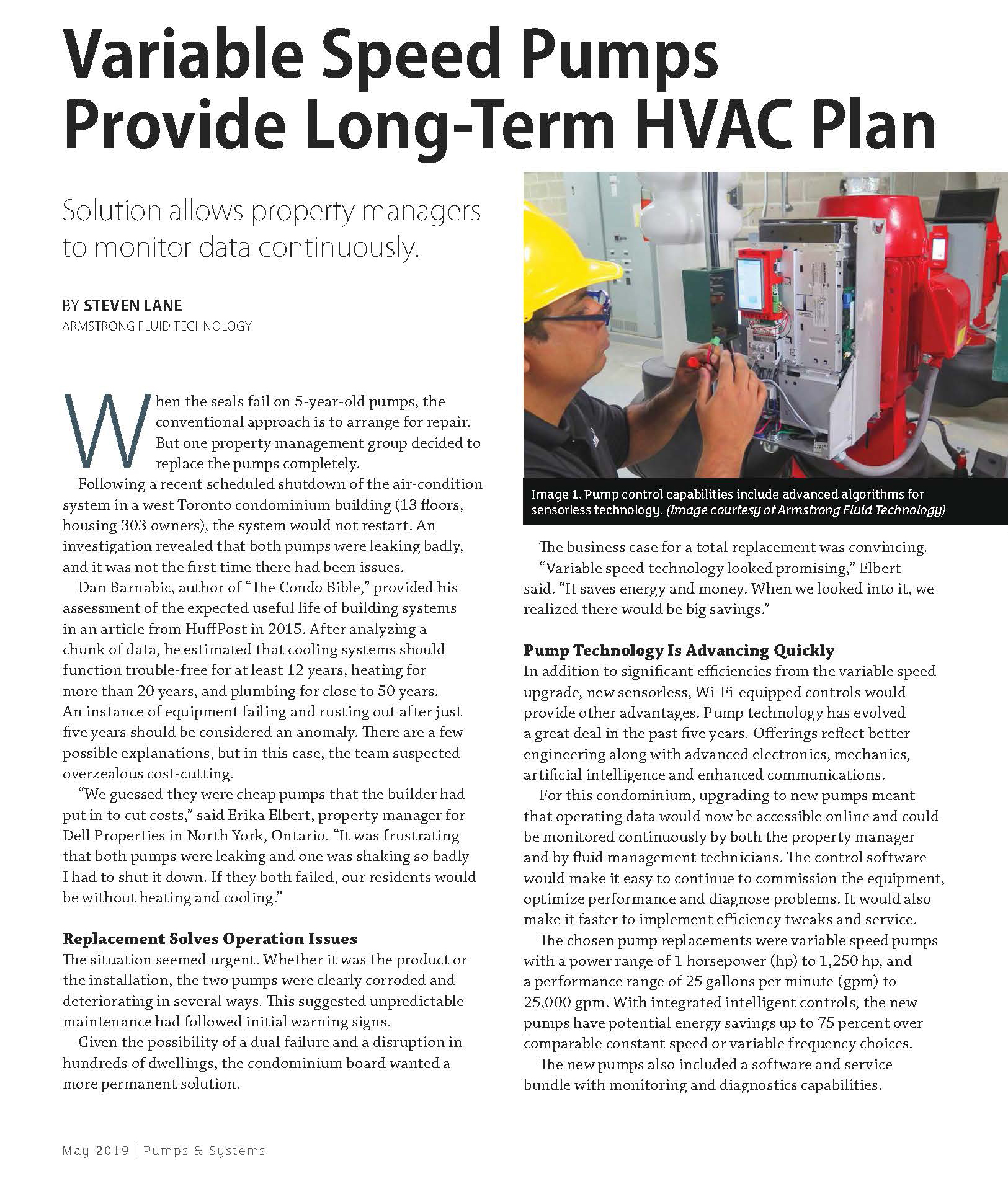

The pump solution incorporates six large Armstrong 4300 Series variable speed pumps with built-in inverters, integrated with Armstrong’s IPS 4000 pump controller, which optimizes the operation of all 6 pumps to minimize energy consumption.