Sensorless Control: Smarter and Simpler

Traditional circulator pumps often require differential pressure sensors to monitor system demand. These sensors can fail, drift, or require recalibration—adding complexity and potential points of failure.

Armstrong’s Sensorless Advantage

Armstrong pumps use motor feedback to calculate system pressure requirements without sensors. This means:

- Simplified installation (fewer wires and components)

- Reduced maintenance

- More accurate, real-time response

- Lower total installed cost

Competitors like Grundfos or Taco may offer similar features but typically require additional accessories or external programming to achieve the same level of performance.

Unmatched Energy Efficiency

High-Efficiency ECM Motors

Armstrong circulator pumps are equipped with ECM (Electronically Commutated Motors) that exceed current global efficiency standards (including IE5 levels). These motors use less electricity and produce less heat, making them ideal for high-performance HVAC systems.

Lifecycle Cost Benefits

While many circulator pump brands highlight energy efficiency, Armstrong provides tangible cost savings backed by real-world data:

- Up to 70% reduction in energy consumption

- Lower demand charges due to smarter operation

- Reduced cooling loads from less heat generation

- Faster ROI (Return on Investment), typically under 2 years for large systems

When compared to brands like Bell & Gossett or Wilo, Armstrong’s efficiency ratings consistently rank among the highest in independent tests.

Flexible Integration with Building Systems

Today’s commercial buildings require more than just standalone hardware—they need smart, connected systems.

Armstrong circulator pumps are designed for seamless integration with:

- BMS protocols such as BACnet, Modbus, and LonWorks

- IoT-enabled platforms for real-time diagnostics and control

- Cloud-based dashboards for monitoring, alerts, and predictive maintenance

This level of connectivity outpaces many competitors who still rely on manual or isolated control systems.

Adaptive Performance for Every Building Type

From schools and hospitals to data centers and industrial plants, Armstrong circulator pumps adapt to a wide variety of commercial HVAC applications. The same cannot always be said for some brands that specialize in either light commercial or residential markets.

Armstrong Works Seamlessly in:

- Large-scale chilled water systems

- Hot water recirculation loops

- Boiler primary/secondary loops

- Multi-zone heating systems

- District energy grids

Whatever the complexity or scale, Armstrong offers a circulator that fits—pre-configured or fully customized.

Retrofit and Upgrade Friendly

Upgrading an older HVAC system? Armstrong circulators are ideal for retrofits.

Why Armstrong Excels in Retrofits:

- Compact footprints for easy replacement of older pumps

- Flange-compatible designs that reduce installation modifications

- Self-commissioning features that eliminate complicated setup

- Integrated isolation valves (on some models) to reduce installation time

Many contractors find Armstrong’s upgrade path smoother and faster compared to brands that require extensive pipework modifications or third-party controls.

Real-World Results: Case Studies

Toronto Office Tower

A 20-story high-rise replaced legacy fixed-speed pumps with Armstrong Design Envelope circulators.

Results:

- 62% energy savings

- ROI in 18 months

- Drastically reduced mechanical room noise

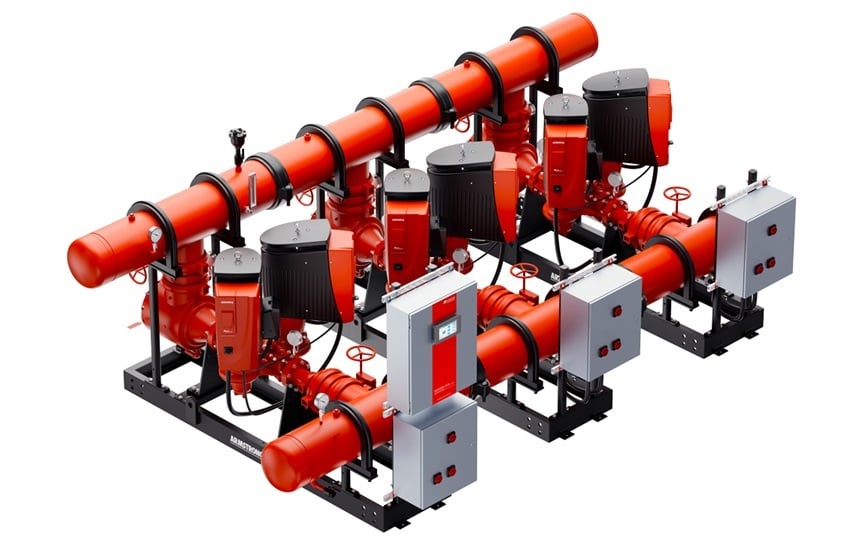

European Manufacturing Plant

A major plant in Germany upgraded its chilled water system with Armstrong’s parallel pumping solutions.

Results:

- 48% drop in electricity use

- 25% lower pump maintenance costs

- Improved temperature stability on the production floor

Few competitors provide the same level of documented case studies showing long-term ROI and operational excellence.

Environmental and Regulatory Leadership

Sustainability is more than just a buzzword. Armstrong is committed to delivering environmentally responsible solutions.

Key Green Features:

- Compliance with global efficiency standards (ErP, ASHRAE 90.1, Title 24)

- Low carbon footprint across the pump’s lifecycle

- Supports LEED and WELL building certifications

Armstrong circulators are often selected in net-zero energy projects and carbon-neutral facilities—something that gives them a strong edge over competitors less focused on green innovation.

Product Range and Customization

Armstrong Offers:

- Inline circulators (Series 4300, 4302)

- End suction and split case pumps

- Dual-armature pumps for redundancy

- ECM smart pumps (Compass H and Compass R)

- Custom-configured Design Envelope units

While brands like Taco or Grundfos offer wide selections, Armstrong stands out for custom factory commissioning, pump modeling services, and personalized BMS integration—especially for complex commercial projects.

Unrivaled Technical Support and Resources

Armstrong doesn’t just sell pumps—they offer end-to-end support, including:

- Online sizing and selection tools

- On-site commissioning support

- Training webinars and certification courses

- 24/7 technical assistance

Their Pump Manager platform gives facility managers a digital interface for monitoring pump performance, tracking trends, and planning maintenance—all in real-time.

This service-centric approach is often more robust than what you’d find with other pump manufacturers.

Trusted by Global Engineering Firms and Contractors

Top mechanical contractors, consulting engineers, and facilities management firms repeatedly choose Armstrong because:

- It reduces installation and operating costs

- It simplifies system balancing

- It enhances building energy performance ratings

- It offers proven reliability in mission-critical systems

Armstrong is frequently specified in large-scale commercial, institutional, and industrial projects worldwide.

When comparing circulator pump brands for commercial HVAC projects, Armstrong offers a rare combination of:

- Intelligent pumping

- Superior efficiency

- Minimal lifecycle costs

- Plug-and-play integration

- Proven reliability

Whether you’re a consulting engineer designing for energy compliance, or a facilities manager looking to cut operational expenses, Armstrong delivers where it matters most.