As seen on pumpsandsystems.com – December 2016

Variable speed pumps in a recreation complex  save a college thousands of dollars per year in energy costs.

save a college thousands of dollars per year in energy costs.

by Brent Ross

Pumping systems consume a significant portion of global electrical energy, accounting for nearly 20 percent of the energy used by electric motors and 25 to 50 percent of the total electrical usage in certain industrial facilities.

Ironically, pumping systems are rarely included in energy-efficiency calculations, even though pumps present such energy-savings potential. One could argue that mentioning “motor” or “variable speed drive” (VSD) is sufficient because these components indicate the greatest energy-savings opportunity in a pumping system.

However, the key to realizing the energy-savings potential is to look at the system as a whole instead of just its component parts. A typical component-part approach might indicate that the motor is 89.5 percent efficient and that there is an opportunity to gain 4.7 percent by switching to a high-efficiency motor.

Specifically, 89.5 percent is the average efficiency of motors used on pumps, and 4.7 percent is the average efficiency increase from the U.S. Department of Energy’s 1998 pre-Energy Policy Act motor efficiency to the National Electrical Manufacturers Association (NEMA) standard 12-12 known as NEMA Premium.

The addition of a VSD may save 20 percent or more, and a higher-efficiency pump could improve pump operation enough to increase efficiency from 74 to 78 percent. This approach yields an efficiency gain of 4.7 percent on the motor, 20 percent overall for the VSD and 4 percent for the pump, resulting in a power savings of 28.4 percent for the entire pumping system.

In this scenario, changing the motor is an easy process because the higher- and lower-efficiency motors are normally interchangeable.

Adding a VSD is a bit more difficult. The VSD must be checked for compatibility with the motor, and this often requires a change to the motor as well. Most motors supplied today are generally compatible with VSDs. The end user also must determine how to control the VSD and at what reduced speed and power level it will run.

One example of a simple approach to control is maintaining a set pressure in the pumping unit. The control components can be in the mechanical room, and installation costs and required system control are minimal. Installing a VSD is relatively easy because any electrician can place the unit on the wall and run the motor power through the VSD before going to the motor. If these simple steps are followed, a VSD installation can save 28 percent in energy costs.

In this example, the owner probably would not change out the pump because doing so could save only 4 percent of additional energy, and changing the pump can be an involved process. The real savings opportunity is in the rest of the system—pipe design, valves and control type, in conjunction with the pump, VSD and motor.

One example of the energy use in a typical pumping system shows 20 percent for the pump, 18 percent for delivered energy, 8 percent for the motor, 29 percent for piping and 25 percent for throttle. The opportunity to save energy is illustrated by the percentage. The example shows that only 8 percent of the energy produces valuable work. The remaining 92 percent is wasted energy and is available for more efficient operation. The motor accounts for only 8 percent of the energy loss, yet that is frequently the main target for energy reduction in systems today.

The second target is VSDs in pumping systems, which, on their own, can contribute limited reduction in the energy consumption of a pumping system. The true opportunity to reduce the 92 percent wasted energy can be realized only by creating an optimized pumping system with minimum hydraulic pipe losses, combined with the proper size and energy-efficient control of the pumping system.

4 Ways to Improve Efficiency

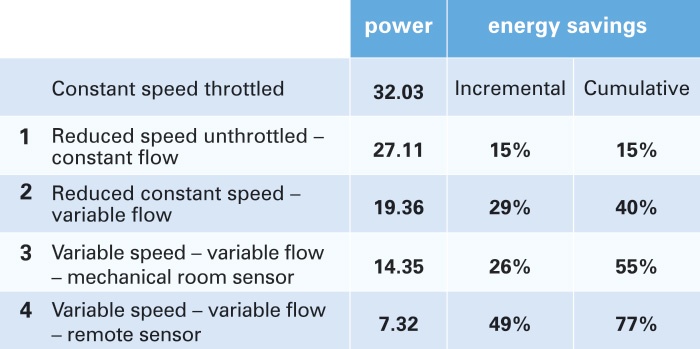

Figure 1 illustrates four opportunity levels for improving the efficiency of a cooling secondary pumping system in a heating or cooling loop in a commercial building. This example starts with a three-way constant-flow pumping configuration that any system installed prior to 1995 probably employs.

Figure 1. Four opportunity levels in a typical cooling secondary pumping system in a heating or cooling loop (Graphics courtesy of Armstrong Fluid Technology)

Figure 1. Four opportunity levels in a typical cooling secondary pumping system in a heating or cooling loop (Graphics courtesy of Armstrong Fluid Technology)

The first level involves installing a VSD and opening the throttling valve in the system. A typical system would have a throttling valve dissipating a percentage of pressure estimated at 15 percent of the system’s pumping power. Many systems operate with the variable speed set at a constant reduced speed. This saves energy, but only 15 percent.

The second level of the energy reduction opportunity is changing the system from constant-flow to variable flow in a simpler situation. This can be accomplished by closing the bypass line of each three-way control valve. In this mode, the pump “rides” its performance curve to provide the flow needed by the system. This approach saves an additional 29 percent.

The third level of opportunity involves changing the variable speed VSD control from a constant speed setting to variable speed and controlling it by maintaining a constant pressure across the pump. The heating and cooling industry considers this the easiest method to control variable speed in a pumping system because the control sensors and wiring are all contained in the mechanical room. This system is easy to install and troubleshoot and can save an additional 26 percent in energy.

The fourth level of opportunity for energy savings is to control the pump speed to meet the system’s changing demands. This can be achieved by either placing the control sensor out in the system itself, or by using integrated pump controls to sense the true system flow requirement through electronics present in the pump.

This fourth level of improvement increases energy savings by an incremental 49 percent to a total system energy savings of 77 percent. A number of other energy-saving opportunities have not been included in this example, such as the opportunity to change the motor to a higher-efficiency motor or the opportunity to right size the pump and optimize the selection against load profile to optimize energy use. In a retrofit installation, an upgrade of the pump can increase pump efficiency an additional 5 percent.

Offsetting the savings generated by these four levels of changes is another factor, which discounts the energy savings referenced. This description does not account for the power loss through the variable speed VSD control. These devices are not 100 percent efficient even at full load. The same statement applies to motors as the motor efficiency is reduced as it runs at reduced load and reduced speed.

By looking at the whole pumping system as opposed to one component, the savings in efficiency can be increased from 15 percent or less to 77 percent or more. Also note that most programs today, as referenced in Figure 1, consider only the change-out of the motor, for an average energy savings near 5 percent, or the addition of a variable speed VSD for a savings of around 20 percent. Unfortunately, most energy-savings programs are missing the much larger opportunity to save 77 percent or more.

Case Study

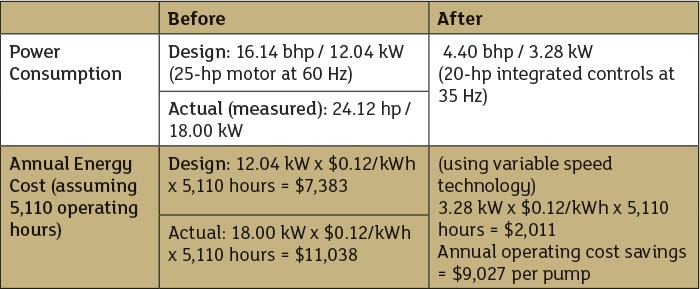

The following case study illustrates the tremendous energy savings available when a facility considers the entire pumping system. Opened in 1972, the recreation complex of a community college contained two new boiler pumps that were installed in 2009. Two years later, technicians measured the pressure on either side of the two pumps and discovered that the pumps were operating at a much lower performance point than originally specified.

The project engineers suggested that the college replace the pumps with variable speed pumps that would adjust operating speed to match the system’s requirements. To make the retrofit as easy as possible and avoid any changes to piping, the facility used the same pump size as originally specified and relied on the variable speed technology to continually adjust speed and pressure.

Table 1. Results of a recreation complex’s upgrade project

Table 1. Results of a recreation complex’s upgrade project

The original specification was for 300 gallons per minute (gpm) at 150 feet of head. The manufacturer supplied two vertical in-line 3×3×8 pumps with 25-horsepower (hp) motors operating at 3,600 revolutions per minute (60 hertz). Following the actual system curve using data provided by the pressure sensors, a new design point was selected at 300 gpm and 40 feet of head. Table 1 shows the results of the upgrade project.

With the installation of the variable speed pump operating to produce the exact flow and head required by the system, the pumps draw only 3.28 kW. Annual energy costs are reduced from $11,000 to $2,000, a savings of more than $9,000 per year for each of two pumps.