When a project has a particularly long timescale it is essential to rethink the HVAC strategy. District energy schemes, for example, are typically rolled-out gradually, linking additional buildings to the network over an extended period (years rather than months).

These types of projects can encounter a number of problems as activities on site expand. Plans change over time and it can be impossible to anticipate exact requirements so far ahead of project completion. From a technical viewpoint, there is an enormous difference between the part-load conditions for phase one and the full-load conditions at full build-out of a project. This presents a significant challenge for HVAC designers, as they need to create heating/cooling schemes that are reliable and energy-efficient over a broad range of operating conditions.

A key decision when designing energy centres for these major long-term projects is whether to start small, or install for full-load conditions from the outset. The established industry habit is to use one of two approaches:

- Installing services for Day One load only: This approach helps to reduce the initial CAPEX but risks premature re-working of the energy centre if the network expands quicker than anticipated.

- Installing all the equipment at day one to meet a future full load condition: This can avoid expensive re-working of the plant room as the network expands but will result in high up-front CAPEX costs. One challenge associated with this approach is variation from original building plans. Not all projects progress as intended. Due to market conditions, buildings can be delayed or even shelved. This can result in the energy centre being oversized for a significant period, leading to in-efficient plant operation, shorter equipment life and a poor return on investment.

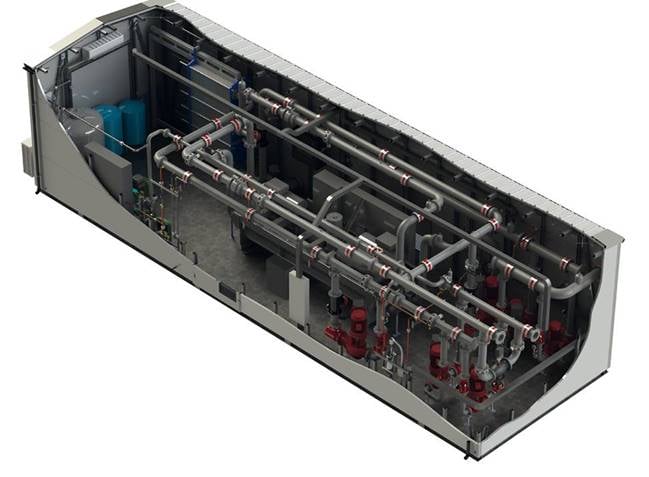

Armstrong has introduced a more effective approach, offering Scalable Energy Centres which can scale-up as required by the changing load profile of the site. The specifier installs only what is needed for the foreseeable requirement of the project at any one time. Once plans and future demand become clearer, additional modular heating or cooling capacity is simply bolted on.

Scalable Energy Centres offer a number of important benefits. Closer matching of heating or cooling capabilities to actual demand avoids the significant technical problems of operating over-sized equipment in the early stages of a project. Preventing over-sizing also ensures that the equipment operates more efficiently, for reduced utilities costs and better environmental performance. In addition, offsite manufacture of the energy centre means less traffic and fewer contractors on site during the build, assembly of the plant room is not delayed by bad weather, and systems are constructed, integrated and tested prior to delivery, speeding installation and commissioning.

Another solution offered by Armstrong is the supply of smaller temporary energy centres, which can be employed during the early phases of a project, and then redeployed later on, making way for full-scale plant rooms as they are needed.

Different schedules, heating and cooling loads and system designs require different approaches, so obviously no one approach can be applied to all projects. However, innovative thinking, properly applied, can produce powerful results. If you think these solutions could benefit your projects, give us a call.

Ends