As Seen On: usgbc.org December 04, 2019

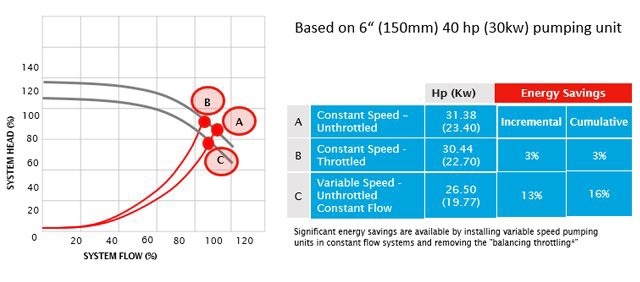

Did you know that it’s possible to save up to 40 cents per square foot, while reducing the timeline to reach your sustainability goals by a third?

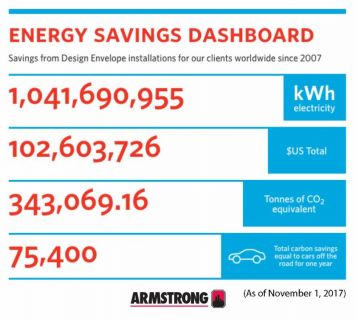

There are few building systems that can have such a dramatic impact on tenant productivity, quality of life, operating efficiency and business sustainability as the HVAC system. Performance drift in HVAC systems is a common issue that leads to wasted energy and increase in greenhouse gas (GHG) emissions. According to the International Energy Agency, the construction and operation of buildings is responsible for over 39% of energy-related GHG emissions, a large part of which can be attributed to inefficient HVAC technologies.