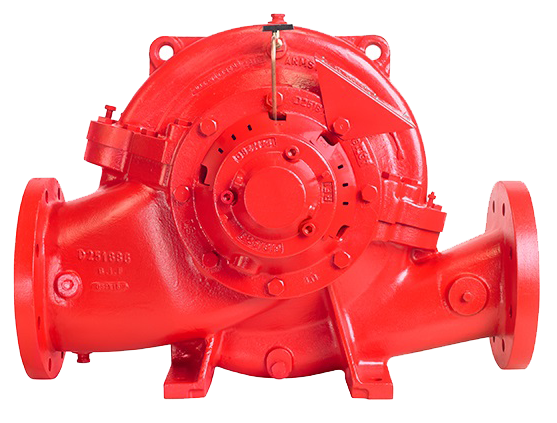

Horizontal Split Case Fire Pump

These pumps use a between-the-bearings design, which means that the impeller is supported by bearings on both sides. This design provides more support for the impeller and enables it to rotate more efficiently under stress. HSC pumps place the suction and discharge nozzles (flanges) in the bottom half of the casing, on opposite sides. The impeller shaft is positioned slightly above the flanges. This sturdy but simple design is particularly suitable for higher flow applications, because it reduces thrust loads on the pump shaft and allows for operation over a broad range of flows.

Important benefits of this design include the availability of pumps in a range of sizes to cover a wide range of flows and heads. The split case design also makes the pump serviceable, without disturbing piping or the driver. These pumps are also commonly available with an electric or diesel drive.

Typical applications for horizontal split case fire pumps include applications requiring higher flows, higher pressures and diesel driven installations.

Advantages of HSC pumps:

- HSC pumps have a smaller footprint compared with a frame-mounted pump of the same rating (in most cases).

- The top half of the casing is easy to remove for inspection of the rotor, and you do not need to disturb the driver or the piping to accomplish this inspection.

- They typically have higher efficiencies than frame-mounted pumps of the same size.

- Because of the dual-eye (dual-suction) impeller design, there are lower net positive suction head required (NPSHR) factors and lower axial thrust.

- This design lends itself to a short shaft with the result of low deflection. This article limits the discussion to one- or two-stage HSC pumps with the impeller situated between the bearings; this design is also known as “between bearings” (API 610- BB-1).

- Typically these pumps offer dual volute construction, which significantly reduces the radial thrust component.

- Unique to Armstrong is a 15-degree angle on our the casing split which allows us to have the suction and discharge flanges in line making it much easier to do pre-piping of the suction and discharge pipe connections in the fire pump room.

Disadvantages of HSC pumps:

- The pump is sensitive to horizontal elbows on the pump’s suction side. Fluid flow through the horizontal elbows induces asymmetrical pressures on the impeller that lead to shortened bearing and seal life.

- The casing does not lend itself to a confined gasket design, so there are consequential horsepower and pressure limits.

- Because the casing halves are truly not halves from a mass standpoint, the pump’s upper and lower portions will expand and contract at different rates with temperature changes, leading to alignment, bearing life and sealing issues. Compounding the problem is the fact that the pump is foot-mounted. The foot design and differing masses restrict the pump from a temperature aspect, so most manufacturers limit these models to less than 400 F.

- The pump can carry increased costs because it has two stuffing boxes, so two seals or sets of packing are required per pump. Many models are restricted in stuffing box sizes that preclude the use of standard or less expensive seals.

- Many claim that these pumps are more sensitive to pipe strain, but this factor may vary based on model and manufacturer.

- While the dual-suction impeller is a benefit from an NPSHR aspect, the shaft running through the impeller reduces the effective eye area, creating problems with suction specific speed factors and multiple issues with any departure from the best efficiency point (BEP). Recirculation and separation issues when operating away from the BEP cause impeller damage and thrust issues.

- This pump design is sensitive to problems with ring clearances. Issues will arise from either the amount of clearance as it opens up from wear or the differences in clearances from one side of the pump to the other. There are also concerns with what is often referred to as “A” and “B” gaps (clearances involving the impeller to casing).

Horizontal Split Case Fire Pump are only one type of Fire Pump, find out about the others here.