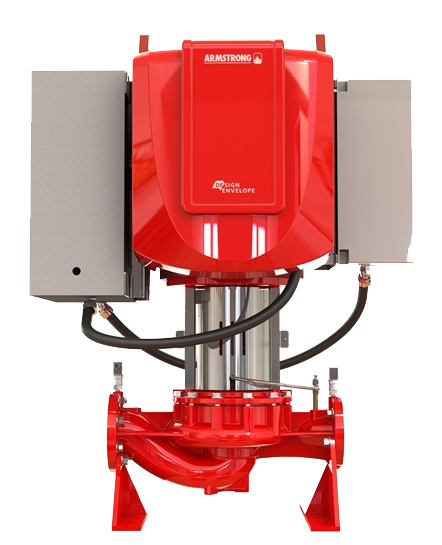

Design Envelope Fire pumps are designed, assembled, and tested to meet the code requirements of a Self-Regulating Variable Speed Fire Pump Unit, as described in NFPA 20 – 2019 edition. Design Envelope Fire pumps are factory-built, integrated fire pumps consisting of a Vertical In-Line pump, driver, and variable speed control unit. They’re configured to maintain a set pressure until the maximum power draw is reached, while modulating pump speed to control to meet limits on pressure or suction.

Applications include warehouses, data centers, high rise buildings and pharmaceutical manufacturing facilities.

Configuration: 50 Hz and 60 Hz designs. UL, ULC, and/or FM certified solutions available (Pending approval)

Performance range: 300 USGPM -1500 USGPM

Temperature: Maximum ambient temperature + 50°C

Power Range: Minimum – 20 Hp (50 Hz) 30 Hp (60 Hz)

Maximum – 250 Hp (50 Hz) 150 Hp (60 Hz)

Key points of value for Design Envelope Fire Pumps:

-

Lowest Installed cost

Because design envelope fire pumps allow building designers to reduce the number of PRV's installed, the overall fire sprinkler system is more reliable, and less costly to purchase and install.

Design envelope fire pumps are also faster and simpler to install and commission than industry standard HSBC fire pumps.

-

Flexibility in System design

With the reduced number of PRV's required for a fire sprinkler system, there are fewer overall components to purchase and install. More importantly, the design of the piping system is much more straightforward. Standard piping arrangements requiring PRVs Hmm demand that PRVs be accessible, and even easily visible, which can require extra corners and pipe sections. With no requirement for PRVs on certain floors, piping sections can be straight and simple.

Design envelope fire pumps use a vertical inline configuration for the pump, and integrate the variable speed controller. This means the complete assembled unit requires less floor space in the mechanical room. In some situations this allows for more rentable space for the building owner. In other situations, the additional space is used to make the fire pump system more easily accessible for installation, and maintenance.

Design envelope fire pumps also reduce the number of peripheral components in the sprinkler system. On any floors that require PRVs, drains are also required. Wherever PRVs can be removed from the design, drains are no longer required.

Because of the variability in supply pressure, system designers must often build in safety factors, requiring larger and more powerful fire pumps. With the intelligent control provided by design envelope technology, these safety factors are not required. Pumps can be sized for the exact flow and pressure required, because the design envelope technology can account for variability in supply pressure.

-

Transparency of Operating Performance

Design Envelope fire pump systems are provided with a 1-year subscription to the fire manager performance tracking service. Fire manager records data points on municipal supply pressure as well as digital recordings of every instance of pump operation and related data.

Fire manager also provides pump analytics and insights to support condition-based maintenance. Lastly, fire manager can provide timely notifications regarding any impending performance issues.

Design Envelope Fire pumps are only one type of Fire Pump, find out about the others here.