As Seen On: empoweringpumps.com February 01, 2020

As of January 27th, 2020, newly manufactured pumps are required to meet the new U.S. DOE/NRCAN 2020 Pump Efficiency Regulations standards. The primary objective of the new regulations is to reduce energy consumption. Secondary items include cost savings for businesses using regulated energy products, and reduction of unnecessary regulation differences between the EU, Canada, and the United States. While the new U.S. DOE 2020 rules establish minimum energy efficiency requirements, the reality is these requirements represent the least we can do.

Efficiency standards that are more stringent are certainly a welcome change. However, it should be pointed out that there are issues with the methods used to calculate efficiencies (see side bar on page 2). A recent on-demand webinar provides some background on the issue (watch this 29-minute video at your convenience). While the use of the U.S. DOE / NRcan Pump Energy Index (PEI) ratings is valuable to determine a minimum energy standard, the pump with the lowest PEI may not provide the best energy efficiency in an operating environment.

Scope of US DOE / NRcan 2020

|

The issue is that the calculation method does not consider overall efficiency. It focuses instead on efficiency at a particular operating point of the load profile. But that approach doesn’t make the best sense, because HVAC is a part-load application. And although that fact may not be in dispute, it’s not as well understood just how much of the time in any given season requires part-load operation. HVAC systems run at their full output for approximately 3% of operating hours (on average). For the other 97% of a given season the equipment operates below capacity along a range of duty points. What matters for HVAC efficiency, energy savings and GHG reductions is the pump efficiency across the entire range of performance points. In practice, pumps that offer intelligent variable speed control are more than twice as efficient. A Design Envelope pump with a PEI of 0.4 would consume only 40% of the energy a minimally compliant pump would require. And an intelligent connected pump would maintain that high efficiency performance longer.

Naturally then it’s important to select a pump according to the best efficiency across the appropriate range of output. Most design engineers use pump selection software. As part of that selection process they must make sure they’re using software that selects a pump on the basis of a range of performance rather than a single duty point.

Pump Energy Index Definitions:PEI – Pump Energy Index

Pump Energy Index Key Points:The PEI is the PER divided by a calculated minimally compliant PER for the given pump model. The lower the Pump Energy Index, the more efficient the pump is: PEIcl average range is from 0.75 – 1.0 and PEIvl average range is from 0.4 – 0.55. PEIvl is significantly better than PEIcl. |

Unaddressed Energy Opportunities for Energy Savings

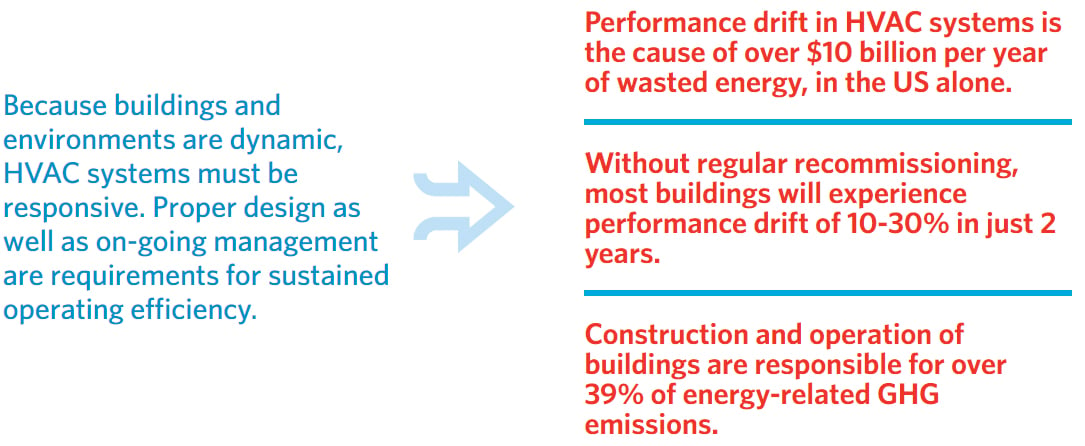

Including pump efficiency in the consideration criteria for a pump is great and using the right approach to find the most efficient pump for the whole range of operating points is even better. But the DOE regulations miss an important opportunity for energy savings. Focusing on new pump installations they will ensure new pumps are more efficient than they might otherwise be, but what about installed equipment in existing buildings? Due in part to established sizing habits, the pumps in most HVAC systems all over North America are over-sized and the energy waste caused by inefficiency is absolutely staggering. In the US alone an astronomical amount of energy is lost every year in HVAC systems caused by performance drift – the gradual degradation of efficiency due to changes in settings or aging of equipment. With so much potential for savings, building owners and operators would be well served to look carefully at their HVAC systems and components and consider retrofits – whether or not they are legally mandated to do so.

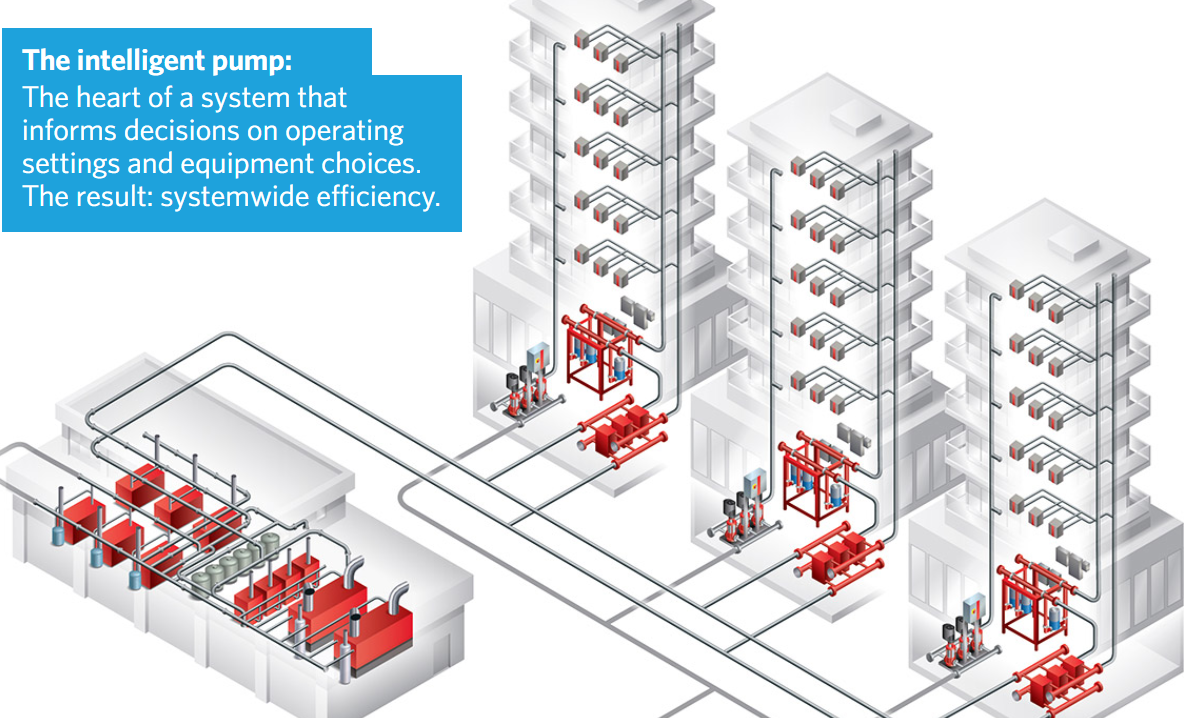

Consider a retrofit project to be a sequential process of finding and leveraging performance date. Don’t start by replacing the biggest energy draw. Start with the component that can tell you the most – your pump.

Most people who take the initiative to start the retrofit process begin by looking at the chiller, assuming this is the biggest ‘energy hog’. Replacing the chiller often produces a change in energy consumption, but delivers no more insight into the performance of the overall system. If instead a project is started with a retrofit to a smart pump, users can obtain detailed information about flow rates and system conditions.

Flow Informs.

The most reliable and informative connecting element in your HVAC system is the fluid flow. Flow rates inform decisions on operating speeds and equipment choices. With flow data to work with, you become empowered to retrofit other system components based on a far more detailed understanding of how the HVAC system operates.

Bring an informed, system-wide perspective to HVAC performance and efficiency. When you take a step-by-step approach to achieving better energy efficiencies based on deepening performance insights, efficiency can improve at every step. At each stage of the project, you’ll have more information to work with and more savings from the earlier stages to help pay for the next component upgrades, so you can upgrade your systems in a manner that is much more financially responsible. Plus, you get to an end result that is so much more impactful than if you just took the approach of retrofitting the ‘biggest piece of equipment in the room’.

Learn more about Energy Upgrades at bit.ly/ArmstrongEnergyUpgrade.