By Wayne Rose

Global Marketing Manager at Armstrong Fluid Technology

In recent years datacenters have been faced with two conflicting priorities. The requirement for cooling continues to increase, driving up energy consumption, but there is also a growing need to reduce carbon footprint.

According to the National Resources Defense Council, datacenter energy consumption in the US is forecast to to reach 140 billion kWh by 2020, making the datacenter industry the largest user of energy in the US.

Similar predictions are being made in Europe. A recent German Federal government report1 estimated that the power consumption of servers and datacenters in Germany totaled 10.1 TWh in 2008, twice the figure for 2000. This equates to the total production of nearly four medium sized coal-fired power stations, and represents almost 6.4 million tonnes of CO2 emissions.

“The days of 'cooling at any price' are over”

In the UK, the introduction of the Government’s CRC Energy Efficiency Scheme adds additional pressure. Figures on energy consumption are reported, with poor performers likely to be ‘named and shamed’. Those organizations with high levels of computer processing capacity will be exposed, more than ever before, to adverse criticism on their carbon footprint. The days of ‘cooling at any price’ are over.

Rethinking the cooling question

Reducing carbon impact is a huge challenge for the datacenter industry though. Every increase in processor speed is accompanied by an unavoidable increase in generated heat. While much continues to be done by IT equipment manufacturers to mitigate these problems through server design, the HVAC system of the building remains crucial to prevent server downtime, as well as reduce energy usage. And as 40% to 60% of annual energy spend for datacenters is consumed by these HVAC systems, ultra-efficient cooling has become a major priority.

Achieving energy efficiency reductions on this scale, however, requires a complete rethink of the way in which chiller equipment is managed. As Marian Vidovic points out in his white paper ‘Ultra-efficient optimization of data center chilled water systems’2, variable speed system components are an integral part of the solution.

“HVAC systems represent 40-60% of energy consumption in datacenters”

“Since a data center cooling system will be required to operate over a greater operating design envelope at varying loads, reliability and efficiency will be mostly required at part-load operation. The most effective method to satisfy the continuously varying and critical demands for data center cooling is to utilize all variable-speed components -- chillers, pumps and fans -- and a control strategy specific to the unique operating characteristic of variable-speed devices. There are no exceptions to this, because constant-speed devices cannot solve the challenges of a varying application such as data center cooling.”

Control methodologies have also had to be redefined. For example, the widely-applied capacity-based sequencing approach to control, which uses on/off cycling, has in many cases proved inadequate for the task. In its place, a new generation of integrated control strategies are beginning to be deployed in datacenter applications which deliver impressive results by balancing demand across the system.

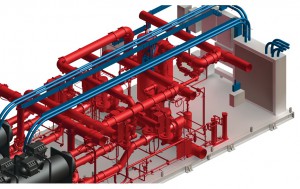

|

| Armstrong Integrated Plant Package (IPP-CHW) |

With equipment of this type installed, plant efficiency of 7.3 COP or greater (on an annual average basis) can be achieved compared to previous best practice COP of between 3.2 and 2.2. This applies not just to the chiller unit, but to the performance of the entire system.

The efficiency is partly made possible by the Natural Curve Sequencing approach of the system’s control technology, which sequences the variable-speed Quantum chillers to operate along their natural curve for all load conditions. There is an ideal point on a chiller’s loading curve for a specific chilled water supply and entering condenser water temperature where that chiller will be operating at its optimum efficiency.

The Armstrong IPP-CHW similarly controls the variable speed pumps so that they also operate along their Natural Curve, or “sweet point”.

In conclusion, datacenters face particular challenges, but the outlook is positive. All-variable speed systems with integrated control are readily available, incorporating proven technology, and can deliver significant carbon reductions.

- Energy Efficient Datacenters: Best Practice Examples from Europe, the USA and Asia. German Federal Ministry for the Environment, Nature Conservation and Nuclear Safety. December 2008.

- Ultra-efficient Optimization of Datacenter Chilled Water Systems. Marian Vidovic, Business Development Manager, S A Armstrong. April 2009.